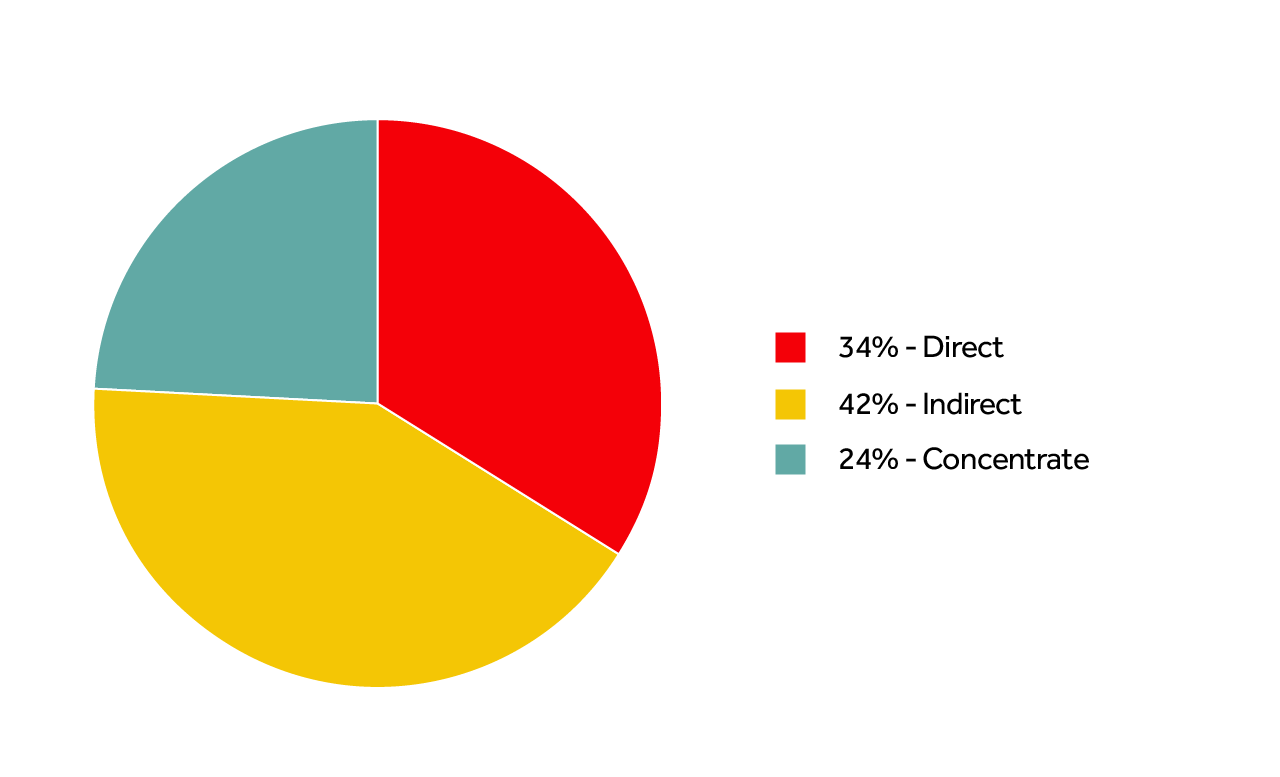

In October 2021, we committed to achieving net zero emissions across our entire value chain by 2040. In 2025 we have embraced SBTN targets and now updating our practices to track FLAG and non-FLAG emissions separately and set respective goals. To address the 90% of emissions in Scope 3 resulting from third party actions, we have broadened our existing partnership approach with suppliers.

To this respect the Procurement Function we launched further collaboration with critical suppliers in Raw and Packaging Categories, reflecting our joint commitment to reduce emissions efficiently in an accelerated manner together with the Coca-Cola System. For example, we have agreed to undertake our first pilot with Nordzucker for beet sugar crop production with control FLAG emissions that will be deployed in 2025.

In Coca-Cola HBC since 2022 we joined the collaborative framework with our key GHG generating Suppliers across the Coca-Cola System to calculate emissions using the Supplier-Specific method (SSEF). This involves gathering suppliers’operational activity data, identifying the right emissions factor(s), and converting the activities to CO2e.

For less mature suppliers we have engaged with Guidehouse on capacity building programs and offer training leveraging the SLoCT program (Supplier Leadership on Climate Transition) every year. This way we are able to help our less mature suppliers build a strong foundation to start reducing GHG emissions.

The efforts we are placing with Suppliers to build their capabilities, have started generating significant results. For example, Egyptian sweeteners suppliers enrolled in the SLoCT program to be supported in their own GHG emissions program development, while our key Sugar supplier in Nigeria, has successfully been accepted as a Bonsucro Member and has secured 100% sustainable sugar crops for our local operations in 2024 onwards.

Since April 2021, when we first launched the Coca-Cola HBC emissions supplier program, we have recruited 187 significant suppliers in the CDP of which 119 have already set or committed to the SBTi, 19% is the average renewable energy of all the suppliers participating in the program.

We engage in a very large number of activities across all our BUs together with our Suppliers to promote the sustainability agenda. Some activities with significant sustainability impact include but are not limited to the following examples:

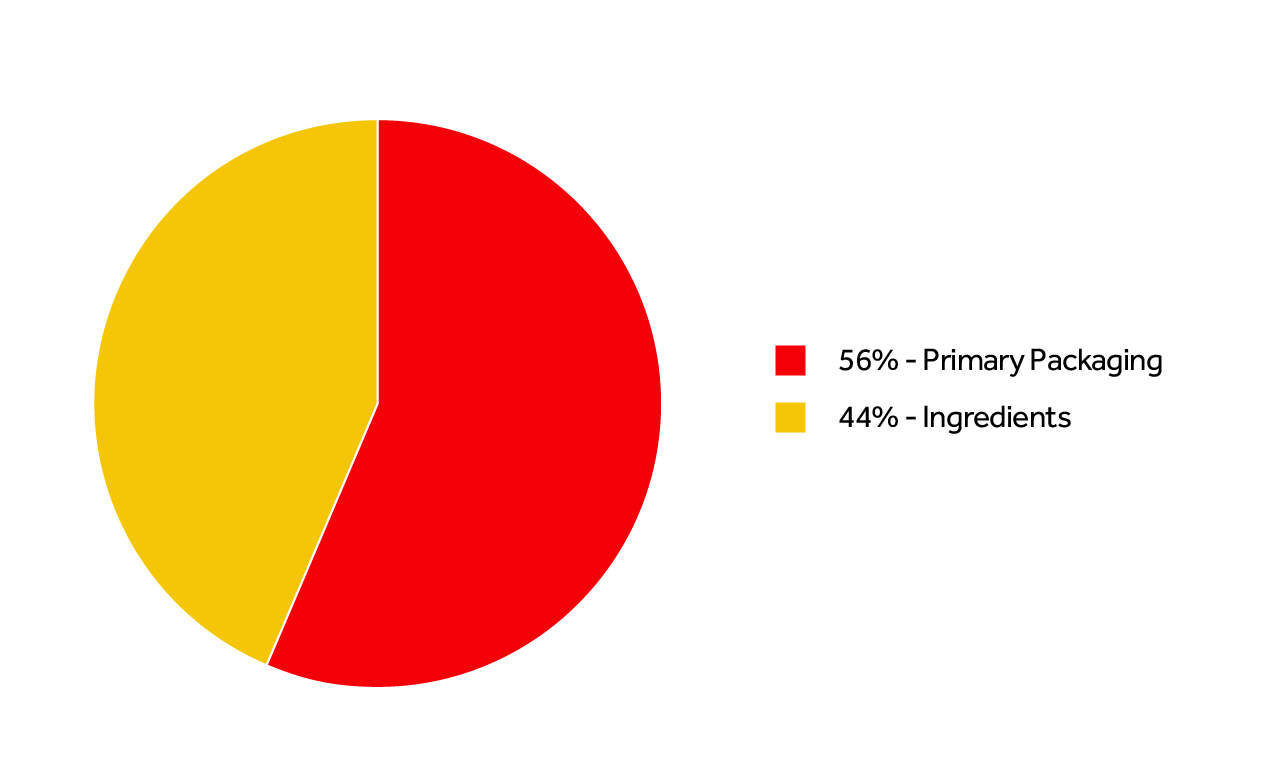

In 2024, we invested €200 million capital expenditure (Capex) on projects supporting the implementation of our climate transition plan, representing 29.4% of total Capex. We also invested [€29.8 million] driven by higher cost of recycled PET compared to virgin PET, as we pursue our strategic objective to reach 35% rPET by 2025, positively influencing both the reduction of our scope 3 emissions and the transition to a circular economy. Our investments in recycled PET manufacturing, for example increasing food grade recycled PET availability. Almost 50% of our requirement for recycled PET are served in-house by the end of 2024, which also reduces costs. In 2024, five of our water brands were sold in 100% rPET bottles. Bottles made from recycled PET have a 70% lower carbon footprint than virgin PET resin, and all electricity used by the production lines is from 100% renewable sources.

We continue to light-weight our primary packaging towards “best-in-class” bottles and Cans in each market, while innovating to remove shrink film from multipacks, optimise closures and labels. We expect this programme to remove an additional 2,800 tonnes of packaging by 2025 vs a 2023 baseline.

At CCHBC, we take pride in our optimised can weights across the portfolio. However, we remain committed to continuous improvement, and recently implemented further weight reductions, achieving an average 1.9% reduction in the can body (Czech Republic, Egypt, Greece, and Italy) and a 9.8% reduction in the can end (Ireland and Serbia).

Bulgaria, Poland and Baltics have been this year the focus countries for preforms optimization with Bulgaria proceeding to insourcing of the 28g preform which translates into a sorter and CO2 optimized supply chain, while Poland and Baltics proceeded with significant reduction in the weight of preforms for the still and carbonated water ranges.

In 2024 we continued to also optimize plastic closures in our Tea portfolio in the Czech Republic, Hungary and Poland saving 50 tons if HDPE per year or 100 tons in GHG emissions equivalent.

After our successful pilot on label height optimisation back in 2023, new labels with reduced height were introduced in 2024 in Romania, Italy, and Poland, achieving a 40-tonne reduction in plastic usage. The project will gradually be expanded further in other BUs as DRS collection systems deployment is evolving in more countries, and we gradually incorporate new label equipment installation as per capital investment plans. The project is expected to conclude by 2026, delivering an annual reduction of 200 tons in plastic usage.

In 2024, Low Density film was successfully introduced for labels in Hungary, Austria, Czechia, Croatia, and Romania, resulting in a 12% reduction in plastic usage. For the remaining EU countries, the introduction of Low-Density film is planned for 2025.

The launch of LitePac Top carton solution in Austria resulted in 153 tn of shrink film removed from our supply chain in 2024. Moreover, we expanded the testing to also Hungary, Romania, Serbia and Ireland. Overall, our experience from the pilots indicated that this solution reduces by 20% on average the amount of plastic previously needed. In 2025 we shall conclude our checks on feasibility for the rest of CCH countries.

In Ireland, Italy, Czech Republic, Poland and Baltics have been particularly focused in shrink and stretch film optimisation initiatives ranging from downgauging and dimension changes to PCR content introduction (Italy) and innovative film implementation (Poland) with an average of 30% reduction in plastic material waved.

For corrugated cardboard since 2023 we have reached > 80% of recycled content in Europe (excl. Russia and Belarus) while we equally focused on optimising material weight. In 2024 for Ireland, we worked with our partner Monster to optimise the trays and save in both emissions and costs, now moving into full implementation in 2025; in the Czech Republic we changed the cardboard composition for corrugated trays to reduce material needed by 33% and in Poland we innovated the pallet dividers to save approximately 3% of paper.

In close collaboration with our Manufacturers and the Coca-Cola Cross Enterprise Procurement group, we deployed since Q3 2023 new cooling technology that reduces energy consumption by 40%. In 2024 we initiated the deployment of the next coolers generation with even higher energy efficiency (Class B) expecting reduction in energy consumption by 45% on average. Our investment in energy-efficient coolers decreases our carbon emissions, improves our sales and helps our customers to save energy and cost.

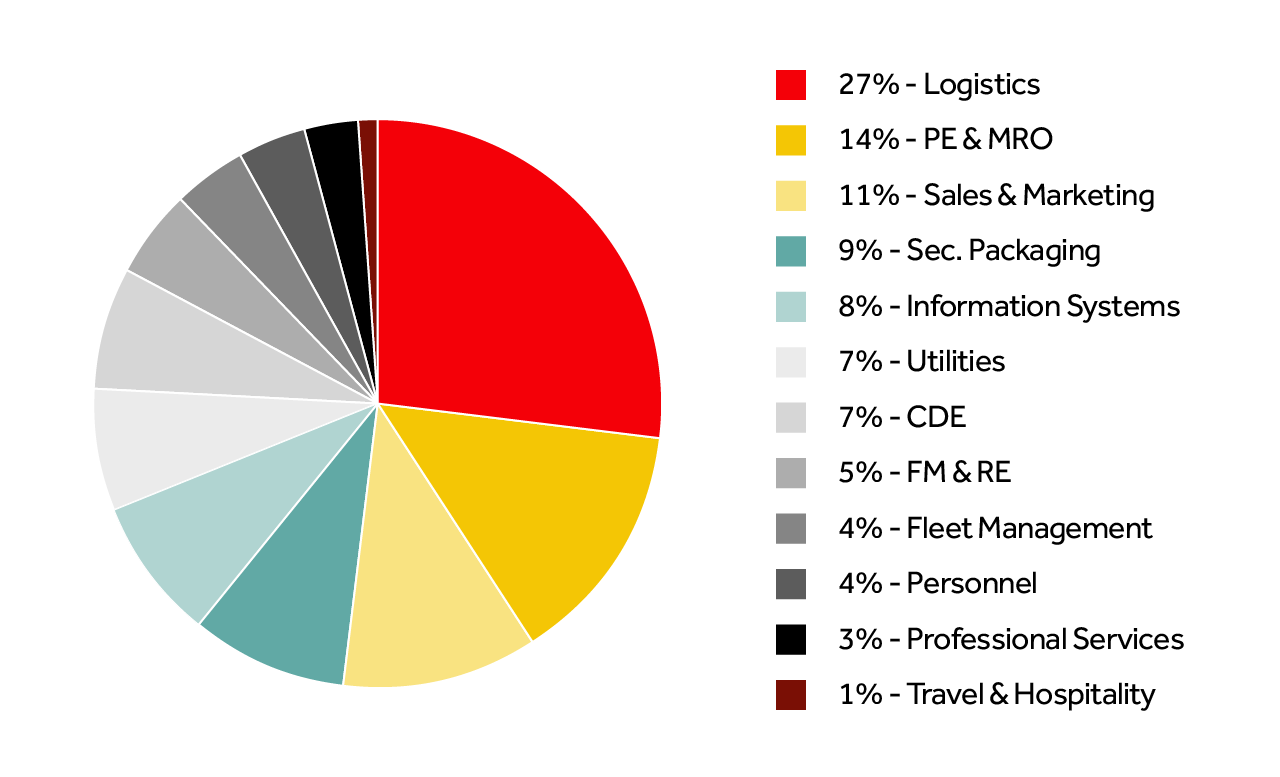

In the field of Logistics and Transportation (include scope 1 fuels used for own transport, both light and heavy, and scope 3 fuels used for outsourced logistics and transportation) we are: optimizing the routes of light and heavy fleet, increasing logistics efficiency and increase heavy trucks utilization; shifting the existing fleet to innovative technologies and renewable or alternative fuels; enhancing the strategic partnerships with our third-party logistics providers and joint investments by means of acceleration for utilizing alternative fuels, route to market evolution, shifting of more volume to trains and other industry innovations.

We have started transforming our vehicle choices and enhance fleet options by introducing an extensive range of fully electric and other alternative power trains such gas and (plug-in) hybrids as part of our plans to continue with our GreenFleet initiative across Coca-Cola HBC and as part of a 5-year plan to reduce the number of ICE Fleet vehicles and replacing with EV from 80% in 2021 to 28% in 2025. For example, in 2024 we continued with Distribution fleet electrification in Austria, and Switzerland and we are initiating Low Carbon Fuel (HVO) in Italy.

We continue to be focused across all our countries to identify and implement energy efficiency optimisations and we are working on pilots to improve on our CO2 yields. We have established the Top 20 energy saver programs mandatory for all manufacturing facilities, that are already in motion and generating results. We are continuing with the investigation of alternative and economically viable sustainable fuel sources; 2024 has been the first year that we reached the agreement for our 1st biogas contract in Ireland. We continue to conduct extensive discussions with key suppliers and exploring the viability of joint long-term initiatives.

For 2024, similar to our 2023 performance, we have managed to source 100% of the renewable and clean* electricity for our manufacturing facilities across our Group. True to our commitment for renewable supply but also generation, we have installed a further 1 MW of photovoltaic generation in Nigeria, bringing the total to 13MW, improving security of supply and reducing carbon emissions. Last but not least, we increased photovoltaic generation in Europe of 1 MW in Czech, Greece and Poland bringing the total installed photovoltaic capacity across all CCH countries to 24 MW.

More examples of key joint activities with Strategic Vendors can be found under the 2024 GRI Content Index, Section 2-6 “Activities, value chain and other business relationships”.